Waterjet

CNC Waterjet Controllers: Cut with FlashCut’s Precision Controls and Integrated Waterjet Nesting Software

Go from design to tool path to full CNC waterjet control, including advanced cornering, pump, and abrasive controls. The FlashCut CNC waterjet cutting process provides everything you need in a high performance control system to streamline the creation of precision parts. Our automatic placement of lead-ins along with our ability to automatically nest parts makes tool path generation a snap.

Our Features for CNC Waterjet Cutting

- Corner slowdown and small arc slowdown

- Multiple pierce options: straight, wiggle, circular

- Corner looping for clean corners

- Support for low pressure mode for glass, marble and other delicate materials prevents cracking

- Separate pierces and cuts

- Adjustable control of low and high-pressure of water and abrasive

- Support the operation of multiple simultaneous waterjets fab-heads

- Advanced formula calculates cut parameters based on material, thickness, abrasive and pump pressure

- Torque based zero sensing (Servo Only)

How does a CNC Waterjet work?

Waterjet cutting machines use a high-pressure jet of water or a combination of water and an abrasive substance to cut a wide variety of materials. CNC waterjet cutting is an excellent CNC application that produces extremely accurate parts. You can cut materials of any type, such as metal, plastic, wood, foam, glass, granite, and even food.

Advantages of CNC Waterjet Cutting

- Can cut into virtually any kind of material

- Does not overheat the material adjacent to the cut thus maintaining its form.

- Produces no hazardous waste

- Highly accurate

- Clean cut that normally does not require secondary finishing

- Can cut thick materials

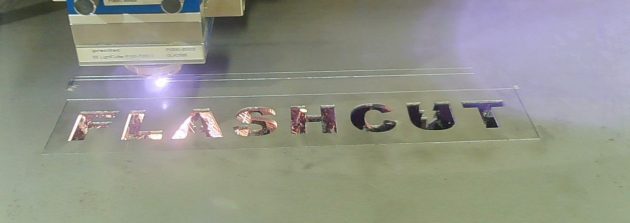

FlashCut offers tailored controls for other 2D cutting technologies such as plasma, oxyfuel, and laser.

FlashCut CNC Waterjet Retrofits

Breathe new life into your existing Waterjet table. FlashCut CNC retrofits are simple and powerful. In most cases, you will be up and running within a day with the latest and greatest integrated FlashCut CAD/CAM/CNC waterjet cutting technology. Retrofits save you time and money with more productivity and less maintenance. In most cases, purchasing a retrofit is more economical than buying a new table.We have successfully retrofitted hundreds of CNC waterjet machines like Omax®, Flow®, Calypso®, Jet-Edge® and others.

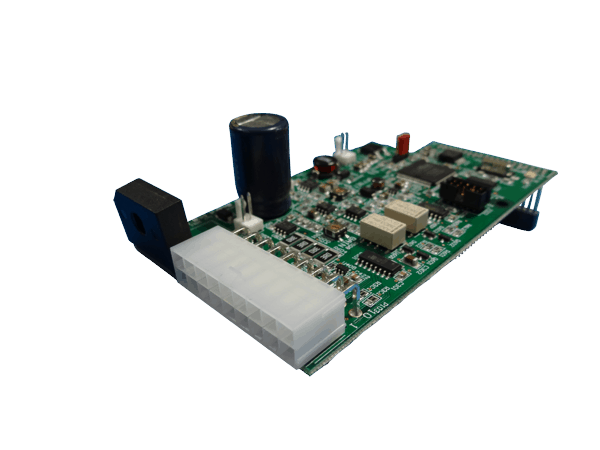

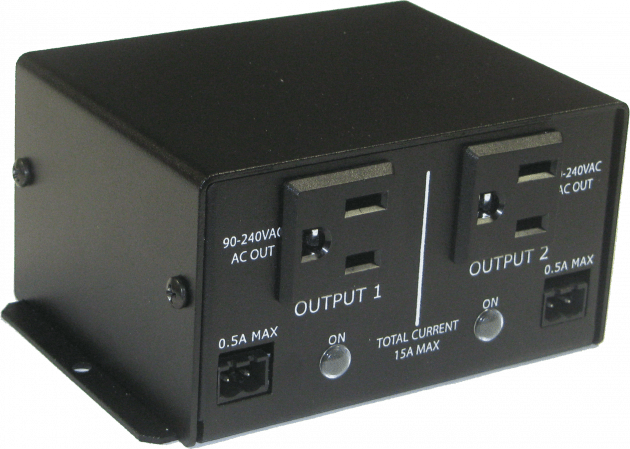

Powerful and Tailored CNC Waterjet Controllers

We have many options for adding state of the art CNC controllers, motors and cables to your waterjet table. Our smooth and precise motion control system will give you accurate, smooth parts with the sharpest of detail.

Our controls work along with advanced cornering tied in with carefully orchestrated control of your jet stream. We offer complete micro stepper and closed-loop servo CNC solutions to drive your cutting machine with precision, power, and ease.

Waterjet Nesting Software

Going from Drawing to Toolpath to Cutting has never been easier. FlashCut’s integrated CAD/CAM/CNC for Waterjet makes it easy to draw a part or import it from DXF or an image and then turn it into a tool path with intelligently placed lead-ins, add perfect kerf compensation, and automatically nest… ready to cut in on your waterjet cutting machine with ease.

Features

Make the most out of your time, your materials, and your machine. Our waterjet software automatically nests parts to ensure exact results and accurate parts while maintaining high performance.

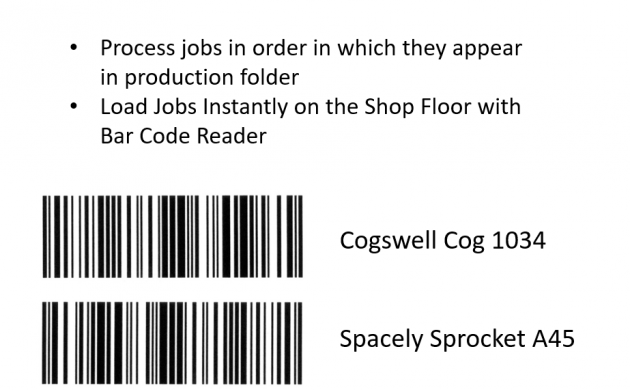

FlashCut CAD/CAM/CNC software has other great built-in or a-la-carte features for waterjet such as collision avoidance and advanced file management for job scheduling in high production shops.